Spray Dryers (Galaxie)

KTV offers Spray Dryers with top quality material and accessories. We are also able to so help clients with advice, changes which may arise, updating existing equipment and transporting. Furthermore, we can provide product testing and drying facilities by third parties, equipment rental and personnel training, as well as auxiliary equipment according to each necessity.

Advantages relating to drying by atomization:

- High performance, due to a very fast process (a few seconds)

- The evaporation of the water contained, refrigerates the particles allowing the usage of high temperatures of drying air, without altering the qualities of the product.

- Continuous process, constantly controlled.

- Homogeneous production.

- Excellent presentation of the product.

- Installation operated by just one worker.

- Easy automation.Installation may operate 24 hours a day.

BRANCHES DIRECTED TO INDUSTRY:

- Chemistry

- Food

- Meat Industry

- Pharmaceutical

- Mining

- Petroleum

Spray Dryer Models

Products that can be dried

1) Solutions, Suspensions, Emulsions and Lyes

- DAIRY PRODUCTS: Whole milk, skim milk, buttermilk, serum, cream, cream for ice-cream, baby food, diet food, malted milk, cream cheese, caseinates, chocolate milk, milk substitutes.

- COFFEE, TEA-MATE: Instant and substitutes.

- CEREALS: Glucose, malt extract, starches, gluten, protein and soybean milk, carbohydrates, maltodextrine.

- PHARMACEUTICAL PRODUCTS: Vitamins, enzymes, antibiotics, sterile human serum, dextran, liver extract, gums.

- PLASTICS: Emulsions of polyvinyl acetate and chlorides of polyethylene, melamine, formaldehyde, products of urea and phenol, acrylic resins.

- DETERGENTS: For delicate clothes and washing machines (beads), washing powder (by means of cooling by atomization).

- FERTILIZERS, HERBICIDES AND INSECTICIDES

- CERAMICS: Clays for kitchen and bathroom appliances, floors, walls, chinaware, ferrites, steatites, kaolin, enamel, porcelains.

- MINERALS: Drying of concentrates.

- INORGANIC CHEMISTRY: Aluminum, sulfur, arsenic, barium, boron, bromine, carbon, chlorine, chrome, fluorine, hydroxides, iodine, magnesium, molybdenum, nitrogen, oxides, phosphorus, titanium, tungsten, uranium, zirconium.

2) Organic Chemistry

- Organic acids: amino acids, salicylic adid. citric acid, maleic acid, ascorbic acid.

- Organic salts: Phthalates, stearates, salicyliates, benzoates, butyrates, gluconates, lactates, saccharates, sorbates and others.

- Subtances containing Nitrogen: Hydrazine, Chloramines, Ureas, others.

3) More Dried Products

- EGG: Whole, egg yolk, egg white.

- YEAST: Yeast, hydrolysis of proteins.

- SLAUGHTERHOUSE EFFLUENTS: Blood, plasma, hemoglobin, gelatins, meat extract.

- FISHERIES BY PRODUCTS: Stickwater, pulp.

- TANNING AGENTS: Vegetal and synthetic tannins, chromates.

- CATALYSTS AND PIGMENTS: Organic and inorganic pigments, anilines.

- EFFLUENTS: Wash waters, high BOD effluents.

- FLAVORS AND AROMAS: Natural and synthetic.

We are at your disposition to discuss and to carry out tests, if necessary, and to verify performance of the system. KTV can also guide you towards the most suited Spray Dryer model for your needs, based on the quantity and characteristics of the products being dried. For further information, please feel free to contact us.

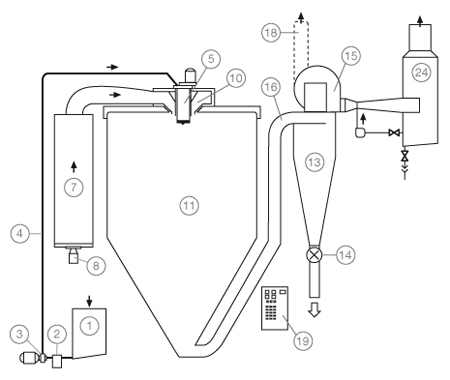

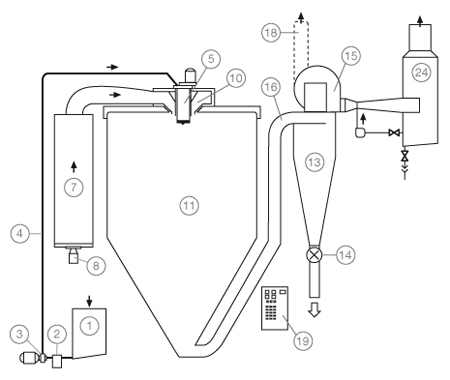

SPRAY DRYING PROCESS

The liquid product is contained in the Feed Tank (1) where from it is driven by the Pump (3) through a Filter (2), the tubing and other accessories to the Atomizer (5).

The furnace Burner (8) and Chamber (7) supply the necessary heat to raise the temperature of the air which, forced by the Blower (15), flows through the Disperser (10) and uniformly spreads around the Atomizer disk (5), delivering the spray.

As the spray clashes with the hot air, drying takes place almost instantaneously on account of particle size.

Lay-out for standard spray drying plant

Lay-out for standard spray drying plant

Part of it being solid (product in a predetermined concentration) it falls in powder form into the Drying Chamber (11) and is aspirated by the exhaust fan, taken along the interconnection tubes (16) to the Cyclone (13) where the powder is separated from the air and extracted as the finished product, which passes through a Rotatory Valve (14) to be packaged.

The separated air escapes to the atmosphere after passing through the Scrubber (24)-(25) that allows recovery and recycling of the product and at the same time, prevents pollution.

Lay-out for standard spray drying plant

Lay-out for standard spray drying plant

1) Feed well

2) Product filtering

3) Measuring pump

4) Piping, valves and fittings

5) Complete Atomizer

7) Hot gas direct generator

8) Burner

9) Ignition system and flame control

10) Hot-air disperser

11) Drying chamber with door and sightglass

12) Automatic electromagnetic hammers

13) Product output cyclones

14) Rotatory valve

15) Exhaust fan

16) Interconnection ducts

18) Chimney

19) Control and operation panel

20) Set of standardized motors

21) Complete electrical wiring

22) Stairs and platform with handrail

23) Support structure

2) Product filtering

3) Measuring pump

4) Piping, valves and fittings

5) Complete Atomizer

7) Hot gas direct generator

8) Burner

9) Ignition system and flame control

10) Hot-air disperser

11) Drying chamber with door and sightglass

12) Automatic electromagnetic hammers

13) Product output cyclones

14) Rotatory valve

15) Exhaust fan

16) Interconnection ducts

18) Chimney

19) Control and operation panel

20) Set of standardized motors

21) Complete electrical wiring

22) Stairs and platform with handrail

23) Support structure

OPTIONALS

- Scrubber for effluent gases before discharge to atmosphere

- Auxiliary atomizer

- Indirect furnace

- Insulation

- Pneumatic transport for the product powder

- Dual ports for product discharge

- Powder cooler

- Powder hopper

- Explosion door

- Temperature recorder

- Other auxiliaries

- Full automation

- Spare parts