EZ-FLO Continuous Weight Scales

The totally enclosed scale works much like a belt scale except it does not have a tachometer.

The totally enclosed scale works much like a belt scale except it does not have a tachometer.Since the scale is totally enclosed, the scale works well containing dusty and light materials that may otherwise be easily blown away by the wind. It does not need a tach since it knows the speed of the material passing through it is constant (gravity).

The flow scale reads the rate of material flow and then calculates a reading based on how much weight passes through it. The two different readings displayed on the Integrator indicates information common to your automobile instrument panel.

The Rate Reading (TPH is much like the speedometer MPH)indicates how fast material is passing through the flow scale and produces an output signal very useful for blending materials.

The Totalizer reading (Tons or other engineering units is much like the Odometer) is used for calibrating the scale, cross checking accuracy, inventory control and producing a signal capable of batching product.

Ranges:

0 to 10 TPH, 10 to 40 TPH, 25 to 100 TPH, 100 to 500 TPH and higher (product density-flowability dependent).

Accuracy:

Up to +/- 0.5% of rate or better (application-calibration-maintenance-option dependant)

Signal output:

4-20ma flow rate.

Optional:

- Calibration Slide Gate, Scale discharge square to round transition, calibration divert stand.

- Automatic Control-Printer.

- Serge Bins-Silos-Feeders.

How it works

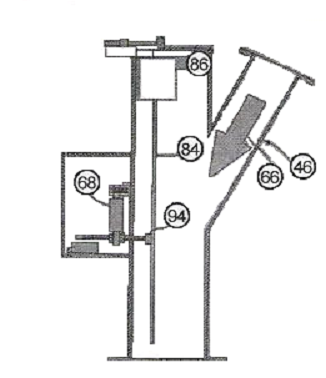

Plate (84) is suspended from a hinge (86).

Plate (84) is suspended from a hinge (86).- Material (66) flows down the feed throat (46) impacting the plate.

- The plate is forced away from the flow against the load Cell Rod (94).

- The force is measured by a load cell (68) and converted into a rate signal.

- The Flow Scale discharges the material as soon as it receives it consequently:

- It can be relatively small in size when compared to weigh pods.

- Venting is not required.

- It only needs one load cell.